toate acestea sunt produse personalizate conform

cerința clientului. dacă este nevoie, putem

furnizați servicii personalizate pentru dvs.

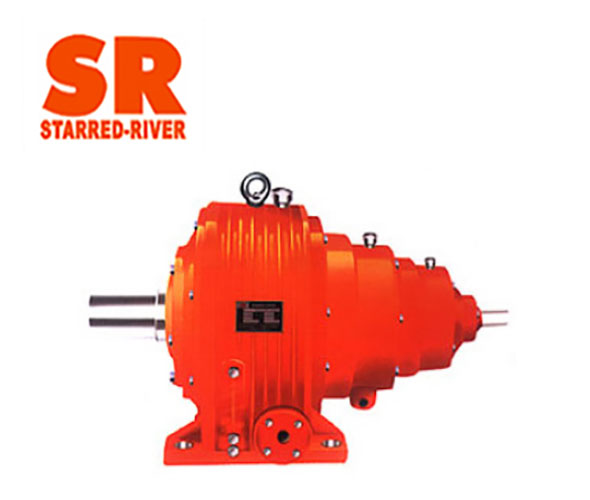

The temperature rise is the temperature difference between the worm gear reducer and the natural environment, which is caused by the hot worm gear reducer. The temperature rise is a key index value in the design scheme and operation, which means the hot level of the worm gear reducer. During the operation of the worm gear reducer, if the temperature of the worm gear reducer suddenly expands, it indicates that the worm gear reducer has a common fault. , or the air duct is blocked or the load is too heavy; the iron core of the worm gear reducer in operation is in the alternating electromagnetic field, which will cause iron loss, copper loss after the winding is plugged in, and various stray losses, etc.

All of these will cause the temperature of the transmission gear worm reducer to rise. On the other hand, the transmission gear worm gear reducer also dissipates heat. When the heat and the quality are the same, the equilibrium state is reached, and the temperature will not increase and will be fixed at a level. When the link is improved or the quality is reduced, the equilibrium will be destroyed, the temperature will rise again, and the temperature difference will be expanded, the heat removal will be increased, and a new equilibrium will be achieved at another higher temperature.

The above introduces the hazard of the temperature of the worm gear reducer during operation. You should understand that if the worm gear reducer exceeds the temperature range, or if the temperature increases suddenly at low load, it means that the worm gear reducer is not very good. If yes, it should be checked and repaired immediately. All mechanical equipment worm gear reducers must be regularly maintained and maintained, which means that long-term operation will cause damage to components, which will lead to certain damage to productivity. The same is true for worm gear reducers. Today I want to share with you The introduction is that if such a worm gear reducer has an oil leakage problem, how should you deal with it?

The oil leakage of the worm gear reducer is mainly caused by the increase of the pressure of the box, so the worm gear reducer should be equipped with a corresponding ventilation hood to achieve pressure equalization. The ventilation hood should not be too small. The simpler inspection method is to open the top cover of the ventilation hood. After the worm gear reducer works rapidly and repeatedly for five minutes, touch the ventilation hole by hand. When the pressure is constant, it indicates that the ventilation hood is small. Resize or raise the fume hood.

Make the oil sprinkled in the inner cavity of the shell flow to the oil pool as soon as possible, and do not keep it at the seal of the bridge shaft to prevent the oil from slowly leaching out along the bridge shaft. For example, there is a skeleton sealing ring on the bridge shaft of the worm gear reducer, or a semi-circular groove is glued on the top cover of the worm gear reducer where the bridge shaft is located, so that the oil splashed on the top cover flows into the lower box along both sides of the semi-circular groove.

What we can do is to improve according to the pressure equalization and smooth flow of the worm gear reducer. In addition, the selection of the worm gear reducer is also very critical, such as the selection of materials, etc. In addition, different materials are used to deal with the problem of oil leakage. The method is also different. The use of polymer material composite materials is used to manage water leakage outside, which saves costs. If the worm gear reducer is running, the packing sealing point leaks oil, and the oil level of the new metal surface treatment technology can be used to quickly repair the adhesive blockage, and then do to clear the oil spill.